Why are Russian optics so good?

© Mahlon G. Kelly

Professor Emeritus,

University of

Virginia.

mgk@comet.net

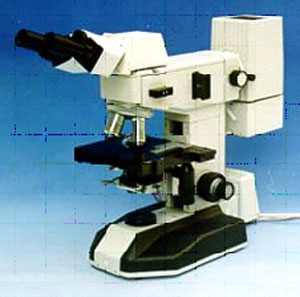

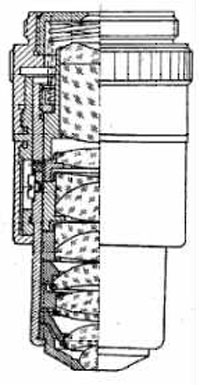

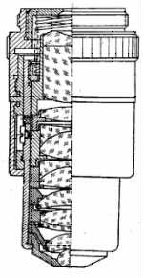

That is a very difficult question. Part of the answer is in the development of the Soviet industry and military. It was recognized by the Soviets in the 1920s that they had to make a tremendous push to develop their heavy industry and military technology. That meant being able to make the tools necessary, and many of those tools were optical. A good example is the development of Soviet microscope manufacturing. In 1936 they contracted with Carl Zeiss in Jena, Germany, to set up a microscope production plant in Leningrad. That firm was called Progress, and they were quite successful. They eventually merged with other companies to become today LOMO, a company we represent. When in 1945 the Soviets captured the Zeiss factory, all of the machinery, and many of the engineers and technicians were transported to Leningrad, and produced the designs of many of the products later sold by Zeiss. Also many prototypes and items that were never seen on the West. Much of that machinery is still in use. While other companies are using computer controlled equipment, plastics, and other shortcuts, LOMO and other Russian manufacturers are still using hand skills, brass, bronze and steel as seen at the left. Their products are very sophisticated, for example the fluorescence microscope at the right

But it is not that simple. In the mid 1930s the Stalin purges had left many orphans, and they were settled in a special commune in Kharkov, in the Ukraine. At that time, Felix E. Dzerzhinsky was head of the NKVD (later the KGB), and he took the responsibility for those children and teenagers. Somehow it was decided that they should learn manual skills, and that to do that they should make cameras. They made a copy of the Leica II that met all of the quality standards of the original Leica. It was called (like the factory) the FED, after F.E. Dzerzhinsky. During WW-II they were moved to Bredsk, Siberia, and then returned in 1946. At that point FED had made several times more Leica copies than Leica had made of the original.

But FED could not keep up with demand, after a brief trial in produce FED cameras at Arsenal Kiev Factory, another factory was given the contract to make the same camera, but with the name FED-Zorki and finally Zorki. These were made in various versions into the 1970s.

During WW-II there was, of course, need for cameras for photoreconaisance. Russia designed their own cameras and lenses. Beside the large use of FED cameras, most were made in the Krasnagorsk factory, near Moscow, and many think they were superior to German and American instruments.

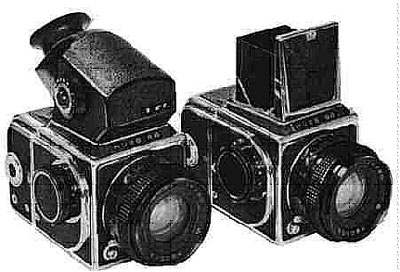

When the Zeiss microscope factory was captured and transported to Leningrad, the Zeiss camera factory was captured and transported to Kiev, in the Ukraine. The company Kiev Arsenal was given the job of making copies of the Zeiss cameras, and the early ones even used captured Zeiss parts. That is a bit strange, because Kiev Arsenal is a company dating back to the 18th century, making cannon, But known in all Russia as the top level precision industry. They basically made copies of the Zeiss Contax, but they made many improvements in the optics. At the same time, Kiev Arsenal had another strange job. The Germans had designed a medium format single lens reflex camera. The design was found by the Allies, and a contract was given to Hasselblad in Sweden to make it for the west, and to Kiev Arsenal for its production in the Soviet Union. That camera is still made, and the present version is known as the Kiev-88, shown at the left. It sells for about 1/5 the price of the equivalent Hasselblad, and independant tests of the lenses show them to be as good or better than the Zeiss lenses made for the Hasselblad.

At this point it sounds as if the only thing the Soviets did was copy other designs. But that is wrong. Beginning in the 1920s, they recognized the need for basic research and education in optics. What is now called the Vavilov Institute in St. Petersburg was formed for basic research. There, soon after the War, Russians and Germans, started an instrument developing program which resulted in a series of amazing prototypes in seeing, reconaissance, topographic and research instruments, gun sights and photographic and movie cameras of top quality, and extraordinary optics, once costs were not a decisive problem. Another University Optical Institute was also formed in Leningrad, mainly for education and training; it is a very large institute giving up to the Ph.D. in optical engineering. Virtually all universities in the former Soviet Union had either departments of optics, or an option for optics in the physics department. That is very unlike any US or other university

So what came of all of this independant research and effort? Some of the results are still secret. But others were never secret. Maksutov, since the early 1940s had worked with mirror telescopes, and in 1955, developed a camera objective based on lenses AND mirrors that let a 1000 mm camera lens be produced that was only 8 inches long. He also designed microscope objectives that, with mirrors, could work at wavelengths impossible using normal optical glass. Roosinov also designed extraordinary wide angles for precision map making , and Rostinov has given us extraordinary resolution lenses. Another scientist, name unknown, designed a microscope objective that could be used in direct contact with a biopsy sample in the operating room to see if it was cancerous in about a minute, without having to send it to the lab. Perhaps the best example is the development of planapochromatic microscope objectives, such as the one shown on the left. These were developed in the early 1950s, and it is argued whether they were developed by interned Zeiss engineers, or Russians; nevertheless they were introduced first in Russia, and now have been made by all of the major microscope manufacturers. We sell them for about 1/10 the price from the best German companies. Lytkarino in Moscow also made the largest telescope mirror ever, with 6 meters diameter. It took 2 years for the controlled cooling of the blank, and 4 years to cut and polish it.

And of course

the Soviets made all of their optics for their space effort and satellite and

air reconaissance. The US. on  the other hand. was dependant on foreign

makers. For example, the cameras in the early NASA satellites were either from

Wild, in Switzerland, or, if hand held, or multispectral imaging, were clusters

of Hasselblads from Sweden. Recently various independant camera magazines have

compared, on the optical bench, Russian lenses with those from other companies.

The results were almost always that the Russian lenses were as good or

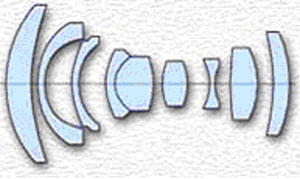

better, even to the most outer edge of the image. And the lenses range from a 17

mm fisheye, to the 1000 mm Maksutov mirror objective mentioned above. The

sophistication of the design and manufacturing is shown in the 20 mm objective

NOT a fisheye, at the

right.

the other hand. was dependant on foreign

makers. For example, the cameras in the early NASA satellites were either from

Wild, in Switzerland, or, if hand held, or multispectral imaging, were clusters

of Hasselblads from Sweden. Recently various independant camera magazines have

compared, on the optical bench, Russian lenses with those from other companies.

The results were almost always that the Russian lenses were as good or

better, even to the most outer edge of the image. And the lenses range from a 17

mm fisheye, to the 1000 mm Maksutov mirror objective mentioned above. The

sophistication of the design and manufacturing is shown in the 20 mm objective

NOT a fisheye, at the

right.

Russian optics have excelled in other areas as well. For example, they make a wide range of total stations, theodolites, levels, and other surveying equipment, as at the right. The accuracy equals or surpasses that of the best German and Japanese companies. Of course that should not be surprising, because one of the Soviet goals was to map its vast area, and of course the development of heavy industry meant surveying.

The Russians also put a great deal of effort into the development of night vision devices. Of course that was mainly for the military, but now the technology has been applied to a variety of consumer designs. The Russian devices are of the very best quality, very rugged, and range from simple hand-held monoculars (at left) and binoculars, through head-strap goggles, to third generation rifle scopes now issued to the Russian special forces (but those cannot be exported from Russia). Some argue that US instruments are better, but one-on-one comparison has shown that not to be true.In fact we have sold Russian instruments to various governments and SWAT teams, in preference to US made units.

Of course they also make a wide range of daylight vision optics such as spotting scopes and binoculars. We particularly like the roof prism Fotons at the left. They are very lightweight, water resistant, and have very bright images because of the roof prism design and special coatings. We also recommend the rubber armored and especially strong military binocular. Also very useful are the "Stabiscopes". These are binoculars with an internal inertial gyroscopic mechanism with no energy needs that prevents hand shake or any other vibration from moving the image. In other words, if you use one of these from a boat on a rough sea, or a vehicle while trying to track wildlife, the image will not move. We have sold several to Africa for work with wildlife, and also to the US Coast Guard.

Of course we must mention price. While quality is not compromised, the prices for Russian optics are, considering the quality, by far the best in the world. That is really incredible, the best products are also the lowest priced. And because we, through our partner firm in St. Petersburg, deal directly with the factories, we offer the best prices in the West.

Finally, and for some this may be the most important, we have very close contacts with individuals and firms in Russia that can design and produce nearly any optical or photonics instrument. And we can do it quicker and for less price than anywhere else. For example, we recently produced a microscope objective capable of high resolution both in the visible and the far infrared. Nothing like that had ever been done before. An Oriental firm tried to do it for our customer, and failed. It took them a year, and cost more than $3000. We produced 2 satisfactory prototypes for the customer to choose from for $500, and they were ready in 5 weeks.

I hope that the above shows you that the Russian optical industry is as good as any in the world, and that if you want to work with Russian optics, we are the ones to help you

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx

SOME BACKGROUND AND HISTORY:

We sell very high quality microscopes from Russia. Having used microscopes since 1957, both for teaching and research. I was very impressed with these units. I was also impressed with the scopes when I used them in the 1970s in England. After visiting the factory, I have learned that their heritage goes back to Zeiss in the 1930s. I also discovered that the manufacturing methods include hand-workmanship that no other company today can afford. These instruments are made to quality standards available nowhere else.

Mahlon G. Kelly. Prop., Professor Emeritus, University of Virginia.

The firm that manufactures our light microscopes, LOMO (Leningrad

Optical and Mechanical Organization) in St. Petersburg, (formerly Leningrad),

was set up by Carl Zeiss technicians in 1936, and in 1945 they were supplied by

the Soviet government with equipment, technicians, and engineers captured from

the Carl Zeiss factory in Jena, Germany. I have been told repeatedly by the

Russian workers: "My teacher was taught by the Germans, and we learned not only

the skills, but the work ethic." Indeed, they work to the very highest

standards, although their pay is about $100 per month.

The firm that manufactures our light microscopes, LOMO (Leningrad

Optical and Mechanical Organization) in St. Petersburg, (formerly Leningrad),

was set up by Carl Zeiss technicians in 1936, and in 1945 they were supplied by

the Soviet government with equipment, technicians, and engineers captured from

the Carl Zeiss factory in Jena, Germany. I have been told repeatedly by the

Russian workers: "My teacher was taught by the Germans, and we learned not only

the skills, but the work ethic." Indeed, they work to the very highest

standards, although their pay is about $100 per month.

To understand the quality of Russian Optics and Microscopes, it helps to know some history of the company. In 1936, under contract to the Soviet government, Carl Zeiss of Jena, Germany, equipped and started a factory in Leningrad to make microscopes. That factory was called "Progress", and their first instrument, shown here, was the OM3 (the one shown is serial number 1). It was identical to the Zeiss Medium Routine Diagnostic Microscope, with the Zeiss designation EOA. The objectives of that scope were identical to the Zeiss achromatic objectives of 8x, 20x, 40x, and 90x, and the eyepieces were the same as 7x, 10x, and 15x eyepieces of Zeiss. LOMO still makes those objectives and eyepieces.

At that time, and into the 1960s, Carl Zeiss was the unquestioned leader in microscope technology. Abbe, Zeiss, Koehler, and the glassmaker Schott, were responsible for the scientific formulation of microscope optics and technology. The design of microscopes everywhere in the world followed the lead of Zeiss.

By 1940 Progress was making not only the simple OM3, but also microscopes equivalent to the Zeiss "Large Universal Microscope", the "Large Routine Microscope", and the "Medium Routine Microscope", that is, all of the basic units of the Zeiss microscope line. There is a rumor that Progress also provided components to Zeiss.

Progress also designed some of its own instruments. An example is a very compact medical field microscope. It had the basic frame of the OM3, but the base and stage folded, so that it could be fitted into a small, portable wooden case, lined with velvet and covered with leather. It is the sort of very nice instrument that makes one ask if all "modern" changes are good.

There is little information suggesting that either Progress or Zeiss did much development work during WW-II. We must assume, however, that ideas were formed in the brains of the scientists, whether or not they were put onto paper. But then things changed quickly.

In July, 1945, the Carl Zeiss plant in Jena was captured by the Americans, and the equipment was put onto 4 trains. About 200 of the top engineers and technicians were interned. A few months later the equipment and personnel were transferred to the Soviets. The personnel responsible for cameras were sent to Kiev, while those expert in microscopes were sent to Leningrad (about 150 people plus family dependants).

In the West we assume that captured Germans were badly treated. That certainly was not the case with the captured Zeiss people. I have spoken with some of them, and with several of the Russians they worked with. They were under guard, and they did live in barracks. However, they received better food than did their Russian counterparts. One elderly Russian lady told me that she and her family survived only because the Germans she worked with shared their rations with her. I know of one instance in which the daughter of a German scientist married a Russian. They were separated when the Germans were repatriated in 1953 and 1954. I had the great satisfaction of putting the 2 families in contact again.

The Russians recognized that if they wanted help from the Germans, they must treat them well enough that they would cooperate. I met one Russian who was responsible for driving the Germans from their barracks to the factory. He said that he often became very angry, because instead of leaving at 5 PM, as was the schedule, they would continue to work into the evening and night, at their own volition.

Thus, although the Germans were interned captives, they were provided with an environment for creativity. Most of them hated the Nazi system, and felt their cooperation with the Soviets would be productive. One can debate the morality of this, but in doing so, one must remember that the German army killed more than half of the inhabitants of Leningrad, and more than 12,000,000 Russians, mostly civilians.

It is impossible to say what ideas were developed in Russia, and what were in the minds of the Zeiss people before they were captured. But this is certain. There is a very wide variety of innovations that appeared in both East and West German Zeiss instruments after 1954 when the Germans were repatriated. Those innovations were incorporated into Russian microscopes at the same time. Some of them are:

1) Planapochromatic objectives (at the left). The current Zeiss price is over $3000, while our price is less than $500.

2) Coaxial descending controls for mechanical stages.

3) Coaxial focusing controls.

4) An illuminator in the base of the microscope.

5) Phase contrast with a rotating aperture disk.

6) An optovar, or variable magnification in the microscope head.

During the mid 1960s, LOMO was formed from four other

companies in Leningrad, including Progress. It is

interesting that although Zeiss, for economic reasons, had to

discontinue some of the items that were expensive to produce, LOMO, with its

state support, could continue. Thus, the achromatic-aplanatic condensor shown

here was discontinued by Zeiss, but is made by LOMO to the present day. It is

much superior to other designs, because the diaphragm may be moved off center,

allowing oblique illumination of the specimen. There are many other

examples.

interesting that although Zeiss, for economic reasons, had to

discontinue some of the items that were expensive to produce, LOMO, with its

state support, could continue. Thus, the achromatic-aplanatic condensor shown

here was discontinued by Zeiss, but is made by LOMO to the present day. It is

much superior to other designs, because the diaphragm may be moved off center,

allowing oblique illumination of the specimen. There are many other

examples.

Light microscopes, although very sophisticated instruments, and requiring very precise work, are not "high tech", in the sense that the basics of the optical and mechanical designs were understood and produced many years ago. In fact, many of us would argue that microscopes of the 1930s were better than those of the 1990s.

LOMO recognized this, and did not change Zeiss components that had been perfected, although other companies were forced to do so for economic reasons. Thus the low-end LOMO objectives (achromatic and apochromatic) that are made today are identical to the objectives made by Zeiss in the 1930s.

On the other hand, LOMO did innovate. In 1969 they had more than 1000 objectives, more than 56 eyepieces, and more than 12 condensers in production. Many of those, such as contact objectives, and dark-field phase-contrast units have never been seen in the west. Also, LOMO made many one-off instruments, for example for testing the strength of wood fibers and for examining the interior of reactor cores. Even now we are searching for one-off and small quantity OEM work.

The result of this conservative approach has been that LOMO parts can be used for many Zeiss and other instruments. For example, the LOMO condensors, heads, objectives, turrets, and nosepieces will exchange exactly with Zeiss, Aus Jena, Olympus, Reichert, and Wild scopes through the 1980s. Our phase-contrast and dark-field accessories can be used with a wide variety of other scopes, as can our epi-fluorescence attachment, which a unique LOMO product.

In other words, LOMO is perhaps the last maker of microscopes in the world to maintain the quality standards, and standards of hand-workmanship, that was exemplified by Zeiss in the 1930s. A LOMO scope is unlike any other modern scope. Although modern in all important respects, the workmanship is of the traditional school.

From Russia, with Microscopes

|

|

|

Mahlon Kelly reports that his second career is simultaneously benefiting Russian scientists and technicians and stimulating him. |

|

©2001 Gitchell's Studio/Charlottesville, Virginia |

Does retirement have to be dull? Not according to Mahlon Kelly '60, Ph.D. '68. An oceanographer and ecologist, Kelly took early retirement from the University of Virginia in 1995, frustrated with the amount of time spent writing grant proposals and feeling that the effort put into classroom teaching went unrewarded. He calls his current life, on the other hand, "a tremendous adventure." At its heart is his new venture, GEK Inc. The company imports sophisticated optical equipment from Russia, including instruments designed to custom specifications. About 80 percent of its sales, Kelly estimates, are to biological research and medical institutions.

Kelly once used a Russian microscope during a research sojourn in Scotland and recalls how much he liked it. "You encounter prejudice in America against the quality of Russian goods," he says, "but there are certainly no deficiencies in their optical instruments. They are as good as anything in the world. From grad school on, I did research on phytoplankton, aquatic unicellular plants ranging in size from a thousandth to a tenth of a millimeter. You need a good microscope to see them, so I got to know microscopes."

While a biology concentrator at Harvard, Kelly also got to know Russian literature in translation. "I was just fascinated by Russia," he recalls. "I had always wanted to see the country, so when a chance came up for me to visit a microscope factory in St. Petersburg in 1995, I jumped at it." He was impressed to find the engineers and technicians "still working to the highest pre-war German standards," painstakingly assembling instruments from brass, steel, and glass. He realized that if he could arrange to import the microscopes to this country, customers would be happy to buy the high-quality products at comparatively low prices, and the factory could stay in business.

He was also aware of the difficulties he might encounter in trying to do business in Russia. "Much business within the country is done by barter, because bank checks are still illegal," he explains. "In addition, export duties are extremely high, and bribery is common. The basic problem is the amount of commercial law remaining from the Soviet era, which I think badly needs updating." But he was "lucky to find a company that was honest right away, and their representative now spends half of each year here with us."

With the most urgent problems solved, Kelly finds it stimulating to meet and talk shop with Russian engineers and technicians. "I'm fortunate," he observes, "that my interpreter and now right-hand man, Andrei Kabluka, is literally a rocket scientist, who works with us because funding has dried up in his field." Kelly has also relished participating in the development of a new scanning electron microscope with a talented engineer from the "science city" of Chernogolovka, a once-secret site near Moscow. "I hope to arrange the financing so that we will be the sole marketer for this instrument outside Russia," he notes, "but I have to admit that my main motivation is not to make money."

Would he advise fellow alumni to try their own second-career projects? "Absolutely," says Kelly. "I believe in doing what you enjoy. You know what they say: 'The difference between men and boys is the price of their toys'--and I happen to think microscopes are really great gadgets." ~Deborah Schneider